HULK EARTH ANCHORS

HULK Earth Anchors

Proudly designed and manufactured in Australia, HULK Earth Anchors are backed by more than 27 years of experience in the field of percussion driven tipping plate anchors.

BENEFITS OF THE HULK EARTH ANCHOR SYSTEM

HULK Earth Anchors are driven into the ground, not augered or torqued, saving time and money. They are environment friendly as no digging or excavation is required during installation resulting in no disturbance or displacement of the surrounding soil. As part of the installation process, the anchor is proof tested to the desired capacity and is then ready for immediate use. Hulk earth anchors are an effective solution for meeting superior holding capacity requirements.

HOW DO HULK EARTH ANCHORS WORK?

Installation sequence:

- The Hulk earth anchor is driven into the ground to the required depth using a smasher rod, or drive steel.

- The re-usable smasher rod is removed from the Hulk anchor leaving the anchor head behind in the ground.

- A proof tester is used to pull on the Hulk anchor tendon, rotating the anchor in the ground. This process locks the anchor in place while simultaneously load testing to the desired load rating.

Small hulk earth anchors- sledge hammer is used

Large Anchors- conventional hydraulic and pneumatic percussive, drilling or vibratory equipment which is available worldwide.

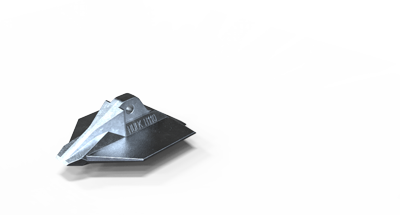

THE ANATOMY OF A HULK EARTH ANCHOR

Hulk earth anchors are the result of years of constant testing and analysis of in situ site conditions and present to the market a product designed for the engineer and the installer.

Hulk earth anchors incorporate a number of significant features which improve its overall performance:

Hex Drive Technology

The unique shape of the Hulk earth anchor body allows it to have a slimmer, stronger profile, we call this Hex Drive Technology. This reduces the amount of effort required to drive the anchor into the ground while simultaneously increasing the overall strength. It also provides a wider scoop on the trailing end of the anchor, encouraging it to rotate and lock into position sooner and more reliably during proof testing. Hex drive also allows for clean angles, allowing the product to galvanise well thereby enhancing corrosion resistance.

Widened Scoop

A further benefit of Hex Drive Technology is the wider scoop on the trailing end of the earth anchor which encourages it to rotate and lock into position sooner and more reliability during proof testing. A major benefit of this is that Hulk Earth Anchors pull back less when proof testing compared to competing brands, thereby requiring a shallower installation depth to achieve similar results- a major benefit for production installers.

Chisel Tech

The “cutting edge” technology of the HULK earth anchor. The chisel like leading edge of the HULK provides superior penetration while driving the anchor into the ground, especially in harder ground conditions.

Ball Nose Smasher

The ball nose “Smasher “anchor driving rods offer superior performance and increased resistance to wear and tear. This also reduces the risk of the rod getting stuck in the back of the anchor.

Tendon Attachment

The Hulk Earth Anchor tendon attachment point is built touch for cable, rod or chain. A wide range of tendons are available to cater for any of your anchoring requirements.

Hulk Deflector

The Hulk Deflector protects the anchor tendon from damage while the anchor is being driven into the ground.

Load Max Technology

The reaction surface of Hulk earth anchors is optimised using clever load max technology. Years of experimentation have shown us that surface bearing angles of an anchor have an influence on bearing capacity. Therefore when we coupled the Hex shape of Hulk with the perfect angled wing, frustum cone angles were increased allowing it our Hulks to carry higher loads. We call this LOAD MAX technology. This wing varies in size across the different Hulk models to cater for varying ground conditions.

HULK HP RANGE

Note: Anchor holding capacities are tendon and soil dependent.

HULK HP25

| Weight | 0.017Kg |

|---|---|

| Material | GRP Plastic |

| Mechanical Properties | Tensile Strength: 5kN |

| Soil Bearing Surface Area | 18.42cm² |

| Typical Installation Depth | 0.6m to 1.2m |

HULK HP35

| Weight | 0.285kg |

|---|---|

| Material | Ductile Iron |

| Mechanical Properties | Ultimate strength: 30kN Yield Strength: 19kN |

| Soil Bearing Surface Area | 38.75cm² |

| Typical Installation Depth | 0.9m to 2.5m |

HULK H RANGE

All anchors in the Hulk H range have an ultimate strength of 55kN and all share the same drive rod, this unique feature allows installers of Hulk earth anchors to quickly change from one model to another to adjust for varying ground conditions without purchasing additional installation equipment. All Hulk H earth anchors are available in galvanised ductile iron with a wide range of anchor tendons available. The Hulk H models available are the H50, H80 and H110.

Note: Anchor holding capacities are tendon and soil dependent.

HULK H50

| Weight | 0.75Kg |

|---|---|

| Material | Ductile Iron |

| Mechanical Properties | Ultimate strength: 55kN Yield Strength: 35kN |

| Soil Bearing Surface Area | 69.32cm² |

| Typical Installation Depth | 1m to 2.5m |

HULK H80

| Weight | 0.835Kg |

|---|---|

| Material | Ductile Iron |

| Mechanical Properties | Ultimate strength: 55kN Yield Strength: 35kN |

| Soil Bearing Surface Area | 99.8cm² |

| Typical Installation Depth | 1m to 2.5m |

HULK H110

| Weight | 0.99Kg |

|---|---|

| Material | Ductile Iron |

| Mechanical Properties | Ultimate strength: 55kN Yield Strength: 35kN |

| Soil Bearing Surface Area | 126.6cm² |

| Typical Installation Depth | 1m to 2.5m |

HULK HG RANGE

Similar to the H range, the Hulk HG range of earth anchors all use a common smasher drive steel. With an ultimate strength of 280kN, the Hulk HG earth anchor range are used for heavy duty anchoring applications. Also available with different wing configurations the HG range cater for a wide variety of ground conditions. The earth anchor models HG100, HG180 and HG320 are all available in galvanised ductile iron.

HULK HG100

| Weight | 5.25Kg |

|---|---|

| Material | Ductile Iron |

| Mechanical Properties | Ultimate strength: 280kN Yield Strength: 175kN |

| Soil Bearing Surface Area | 298.96cm² |

| Typical Installation Depth | 2.1m to 9m |

HULK HG180

| Weight | 6.4Kg |

|---|---|

| Material | Ductile Iron |

| Mechanical Properties | Ultimate strength: 55kN Yield Strength: 35kN |

| Soil Bearing Surface Area | 487.76cm² |

| Typical Installation Depth | 1m to 2.5m |

HULK HG320

| Weight | 11.3Kg |

|---|---|

| Material | Ductile Iron |

| Mechanical Properties | Ultimate strength: 55kN Yield Strength: 35kN |

| Soil Bearing Surface Area | 1034.54cm² |

| Typical Installation Depth | 1m to 2.5m |